No products in the cart.

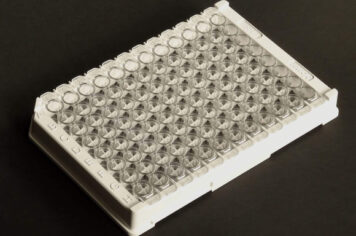

Protein A/G Coated Plates

Protein A/G Coated Plates are designed to provide alternative to direct, passive adsorption methods for immobilizing antibodies for ELISA.

The surface of Protein A/G Coated Plates is a surface that binds to most IgG species (in particular binds to all subclasses of mouse IgG excluding mouse IgA, IgM or serum albumin and to all subclasses human IgG), IgA, IgE, IgM and IgD...

[Read more]

Protein A/G includes four Fc binding domains from Protein A and two from Protein G making it a versatile tool. The binding dependency to pH of Protein A/G is lower than Protein A but has the additive properties of Protein A and G together.

Examples of applications for Protein A/G Coated Plates are:

- specific and sterically oriented bond of antibodies

- purification and detection of mouse monoclonal IgG antibodies and for purification of macaque IgG

- highest specificity and capacity

- retains antibody activity and orients antibody for maximum binding

- generally not suitable for sandwich ELISA assays

Biomat Protein A/G Coated 96 Well Plates are made in Transparent, White and Black Polystyrene and can be used for quantitative and qualitative immunoassays like ELISA, Chemiluminescent (CLIA) , Luminescence (LIA) and Fluorescence (FIA) assays.

Protein A/G Coated Microplates are pre-blocked in order to minimize any non-specific binding and to ensure long-term stability.

Protein A/G Coated 96-Well Plates formats

Protein A/G Coated 96-Well Plates are offered in 3 different formats for maximum flexibility:

- Protein A/G Coated 96 Well Breakable Strip Plates

- Protein A/G Coated 96 Well Strip Plates

- Protein A/G Coated 96 Well Solid Plates

The well can have a volume capacity of:

- 350 µl,

- 360 µl,

- 400 µl.

Biomat Protein A/G Coated Plates main features

Biomat Protein A/G Coated 96 Well Plates are suitable for ELISA Assay Technology and others immunoassays due to these features:

- they are ready to use

- they are manufactured under ISO:9001 guidelines

- they are made in pure polystyrene with low fluorescence

- the mould design provides optical quality, important to reduce the background signal

- the wells inner bottom radius edge improves the efficiency of washings

- the external lid warrants vertical alignment when using single microplate wells

- they are equipped with alphanumeric coding for easy well recognition

- the rim protects the external face of the bottom from scratches

- the microplates comply with SBS standards and the design assures a good performance in automatic processing plant

- all lots are tested for uniformity and reproducibility

- the Certificate of Quality is released for every lot

- for Research Use Only